What is Kevlar? Kevlar is an aramid fiber with its technical characteristics, mostly due to its high strength, is widely used in various branches of the industry. The mechanical properties allows this fabric to be used in the military sphere as a material for making body armor and helmets.

The production of the original Kevlar fabric is produced by the company DuPont. However, today there are many alternative developments of aromatic polyamide fibers, which are created by other companies. These fabrics also have high mechanical strength, in terms of characteristics they hardly differ from the original Kevlar fiber.

The emergence of Kevlar dates back to 1964, which was the year where its technology of production was developed. Industrial production of kevlar began in the early 1970s. After a few years, it was helped to discover the fact that Kevlar-29 and its varieties, which were used as fabric and woven-polymer barriers, consisted of several layers. It was a perfect combination of speed, of energy absorption and duration of interaction with the striker.

As a result, these developments helped to provide bullets and projectile fragments with such good ability to resist.

What is Kevlar Made Of?

Kevlar is made of aramid fiber.

The aramid fiber has the following qualities:

- Flexibility

- Strength

- Durability

Features of the materials in the 1970s, reinforcing fiber from Kevlar began to be used to create body armor. The development of such protective equipment was engaged by the U.S. National Institute of Justice – NIJ. The development process took several years and included four stages.

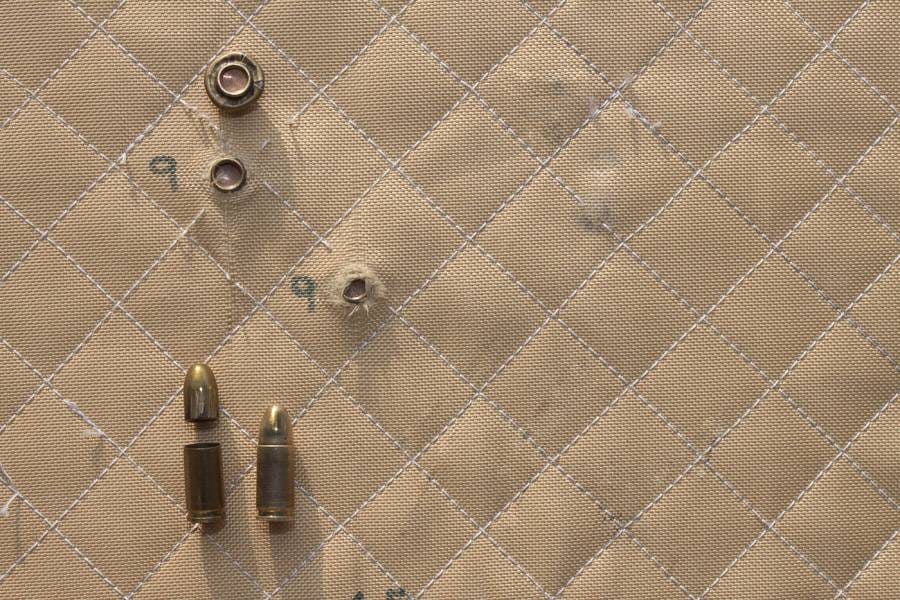

Tests were held to show how we can stop a bullet with such kind of fiber. As a result, it was the growing number of layers of fabric, intended to prevent the penetration of bullets of different calibers, which flew with different speeds. Specialists from different institutes developed a vest that became a prototype of all that had the opportunity to protect its people. It ranges from .38 Special and .22 Long Rifle bullets, which used to be the most common threats at the time.

In 1973, a vest with seven layers of aramid fiber was created for field testing. Developers found that Kevlar lost its chance to protect people when it’s wet or exposed to ultraviolet rays including sunlight. The protective properties of the fibers partly disappeared after dry cleaning, repeating washing, and usage of bleach. To solve the problem, a coating was created for the vest that prevented water penetration and exposure to sunlight. That’s what Kevlar material is..

Features of Aramid Fiber

The main advantages of Kevlar material have high specific ability to be tensile, good resistance to impact, and dynamic load. Kevlar yarn is 10 times stronger than steel yarn of the same mass.

What is Kevlar Thread?

Kevlar thread is a firm matter which is strong to a lot of factors, but it vulnerable for:

- Hot Temperature

- Knives

- Awls

When the temperature is low, Kevlar retains its strength and flexibility, and when the material gets cool, these characteristics even partly improve. When it goes heated to 150°C the fabric gradually loses strength. At 250°C, the strength of the fiber gets half-reduced in 70 hours. When the temperature is high, nearer to 430-480°C, aramid fibers split up.

Kevlar fibers have tensile strength twice as much as Nylon 6,6 ranging from about 2.6 to 4.1 GPa.

Mechanical Properties

| Grade | Density (g/cm3) | Tensile Modulus (GPa) | Tensile Strength (GPa) | Elongation (%) |

| 29 | 1.44 | 83 | 3.6 | 4 |

| 49 | 1.44 | 131 | 3.6-4.1 | 2.8 |

| 149 | 1.47 | 186 | 3.4 | 2 |

Despite all, the excellent ballistic characteristics and the effectiveness of Kevlar helmets and body armor is not limited to the first and second classes of protection in the case of the threat coming from gun bullets. They can’t get through powerful rifle rounds. Sometimes aramid fiber is used as a supplement in body armor released by the metal plates.

The structure of Kevlar makes it vulnerable to knives or awls. It’s quite easy to pierce such fabric because its threads can simply split up. But it is very difficult to cut the aramid fiber. At the same time, Kevlar armor has good softness and flexibility which allow it to be used in cases where you need to hide the presence of protection. The aramid vest fits under a business suit and provides almost complete freedom of movement.

What is Kevlar Used For?

The usage of Kevlar in the manufacture of drones complements the usage of matter in personal protective equipment. Kevlar is used in different cases, but the high cost of making aramid fiber prevents a lot of people from mass production of this material. This fabric was created to reinforce car tires and for this purpose, which is still used today. Kevlar also helps to reinforce fiber in composite materials and it provides them with high strength and lightness.

Aramid fiber is also used in blended fabrics, which is used to produce protective gloves and sportswear inserts. Nowadays, Kevlar is used in building ships while making elements of yachts. Moreover, aramid fibers remain the same in the aviation and space industries. For example, the fabric helps to increase the protection of unmanned aerial vehicles.