Prime Armor NIJ Level III GEN 2.0

from: $27900

- Weight: 10″x 12″ 3.9lbs and 5.4lbs for 11″x 14″

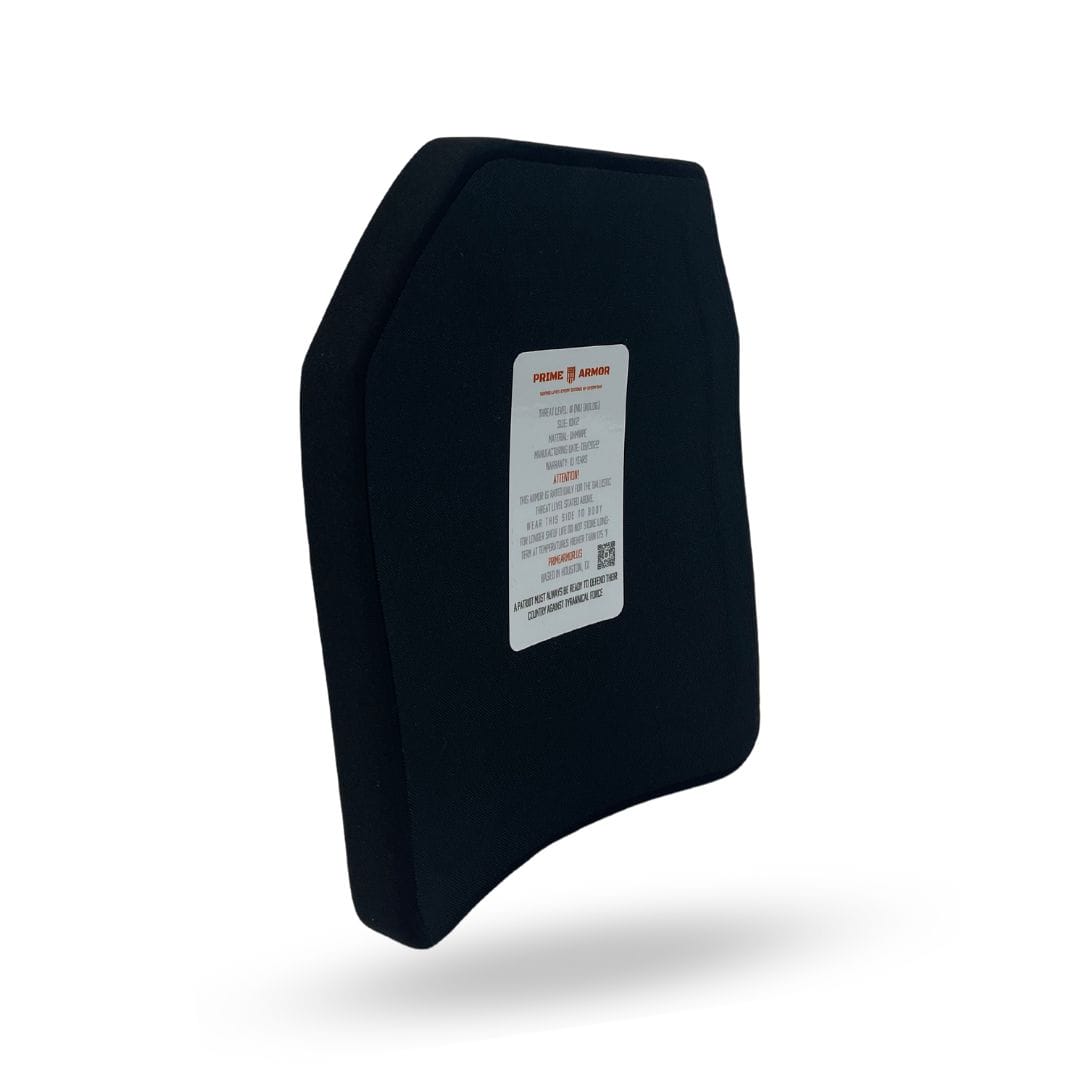

- Coating: 600D nylon w/ edge padding

- Size: Standard 10” x 12” and 11″ x 14″ in SAPI/ESAPI-Cut

BODY ARMOR FEATURES:

- 7.62×51 M80 Ball at 2800 FPS

- 5.56×45 M193 at 3150 FPS

- 7.62×39 AK 47 at 2380 FPS

- 7.62×39(MSC) AK 47 at 2380 FPS

- Tested accordingly to NIJ-STD-0101.06 in accredited NIJ labs

- Also, check this product in Bundle Deals

Description

Prime Armor Polyethylene Body Armor Specs:

- Weight: 3.9lbs and 5.4lbs for 11″x14″

- Coating: 600D nylon w/ edge padding

- Size: Standard 10” x 12” and 11″ x 14″ in SAPI/ESAPI-Cut

Prime Armor Polyethylene Body Armor Features:

- 10 years warranty for Ballistic Components

- Only 3,9lbs in 10” x 12” SAPI/ESAPI-Cut

- Level III rated

- Single and Multicurve available

- Stand-Alone and Multi-Hit capable

- 1.3” Thick Profile

- Positive Buoyancy

- UHMWPE ballistic core construction

- Durable Nylon cover

- Edge impact padding

- Backside impact padding

- Also, check this product in bundle deals

Level III Polyethylene Body Armor weighs is 3,9 lb’s per plate in 10” x 12” standard SAPI cut. This plate has been tested according to NIJ 0101.06 standards, positive buoyancy, stand-alone, and multi-hit capability.

This plate is a great choice for those who looking for rifle protection with a low weight. More comfortable than steel plates. Backside impact padding is added to reduce the amount of energy transferred to your body, reducing felt energy through your armor.

Present to you an ergonomic single curve, our PE (Polyethylene) Level III armor. The plates are not only affordable, and comfortable, but high performing, and lightweight.

Encased in a water-resistant nylon cover with edge impact padding increases durability. 10” x 12”, this armor has a profile of 1.3” thick and carries a 10-year shelf life.

PLEASE NOTE THIS VIDEO IS STRICTLY FOR ENTERTAINMENT PURPOSES AND CANNOT BE HELD AS AN ACTUAL PERFORMANCE OF THE PRODUCT. ALWAYS REFER TO BALLISTIC LAB TESTS THAT ARE PRESENT ON OUR WEB PAGE OF THE PRODUCT.

Additional information

| Weight | 3.9 lbs |

|---|---|

| Size | 10 x 12, 11 x 14 |

| Shape | Single-curve, Multi-curve |

| Armor Level | Level III Body Armor |

Shipping

Prime Armor uses reliable third-party carriers such as UPS and the USPS to deliver our Products to you. In some cases, customer pick-up may be available. Prime Armor uses commercially reasonable efforts to ship Products within one (1) business day after payment for the Products has been received in full when Products are in stock. If manufacturing time is needed for any Product purchased, Prime Armor will contact you with an estimated lead time for the order. Notwithstanding the foregoing, all delivery times provided for in an order confirmation represent approximate delivery times, and actual delivery times may vary as a result of events outside of our control.

Prime Armor is not liable for any damages (including, without limitation, any incidental or consequential damages) arising from its failure to deliver or delay in delivering the Products purchased hereunder. You bear all risk of loss and damage to the Products from the time the Products leave our warehouse or fulfillment house. Delivery is deemed complete and title to the merchandise passes to you upon acceptance of shipment by a common carrier.

Our shipping rates depend on the value and volume of purchased items. We offer free shipping on all orders, however additional fees may apply to oversized or heavy items/orders (over 50lbs). Prime Armor willnotify you of any such fees in advance.

Returns

Due to the lifesaving of the product all body armor sales are final. We want all of our customers to be happy with purchases made through our Website. If you are unhappy with your order, we will accept (non-ballistic) product returns if received by us within thirty (30) days of the date of delivery, subject to the requirements set forth in this Section. Plates are non-returnable unless you experienced obvious damage to your product caused by wrong packaging or delivering an already defective product. Please make sure to inspect the packaging of your item(s) when they arrive, if you notice any damage, you should document it when signing for delivery. If the item(s) contained in the package arrives damaged, please send photos, and we will process an insurance claim on your behalf.

We charge a 15% restocking fee on all returned products and you will be provided with a return label. If you decide to cancel your order prior to shipping a charge of a 5% restocking fee will apply Returns are eligible for 30 days if any visible damage occurs. To initiate a return, please go to our website, scroll down to the bottom, and go to the RETURNS section where the automatic system will guide you through the return process. You are solely responsible for the cost of return shipping to us (except for returns sent under our Limited Product Warranty, as defined below). We are not liable for Products that are damaged or lost in transit to Prime Armor. We recommend that you ship your returned Product to us via a trackable shipment method.

Upon our receipt of the Product at our warehouse, we will inspect the Product and process the return. After the return has reached our facility, please allow approximately ten (10) business days for the refund to be credited to your account.

Only orders that meet the following requirements shall be eligible for return:

- Products must be returned in their original packaging with all tags still attached, and complete with all parts and accessories.

- Products must be in new condition and must not be used, altered, or damaged.

If you are unable to comply fully with this return policy, you may not be entitled to a refund, in whole or in part, at our sole discretion.

Submit a return

Write us a message and we will answer you shortly

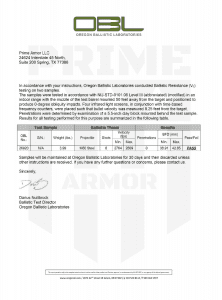

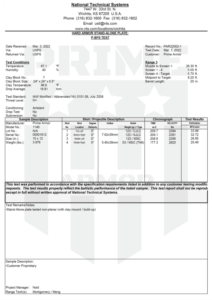

Ballistic Report

You may also like…

LEVEL III

HARD ARMOR PLATE RATED TO STOP 6 SHOTS OF .308 ROUNDS

ONLY 3.99 LBS IN 10'' X 12'' IN SAPI/ESAPI CUT

WILL FLOAT ON WATER

UHMWPE BALLISTIC CORE CONSTRUCTION

10 YEARS WARRANTY FOR BALLISTIC COMPONENTS

ARMOR REVIEWS

THE MOST DURABLE LEVEL III BODY ARMOR ON THE MARKET

SAVE ON WEIGHT AND BE SAFE FROM SPALLING

Level III Polyethylene Body Armor weighs is:

- 10” x 12” – 3.99 lbs

- 11″x14″ – 5.4 lbs

In SAPI/ESAPI cut. This body armor has been tested according to NIJ 0101.06 standard in official NIJ laboratory. Plate has positive buoyancy, stand-alone capability, and multi-hit rated.

ERGONOMIC SINGLE CURVE

WATER-RESISTANT NYLON COVER

PROTECTION WITH A LOW WEIGHT

This plate is a great choice for those who looking for rifle protection with a low weight. Can be used as backpack insert. More comfortable than steel plates. Back side impact padding added to reduce the amount of energy transfer to your body, reducing felt energy through your armor

Our Instagram

FREQUENTLY ASKED QUESTIONS:

What advantages does your plate offer over a similarly priced steel plate?

Prime Armor plates are not only more comfortable and have minimal spall risk than steel plates, but high performance and lightweight – only 3.99 lbs!

Where are your plates tested?

Our armor was tested at OBL (Oregon Ballistic Laboratory ) and with multiple tests from our teams and YouTubers. Protection levels are set by NIJ (National Institute of Justice) and indicate what caliber rounds you will be protected against at which range/velocity. For more detailed explanations of these protection levels, you can see the image above FAQ or visit the NIJ’s website here.

What are typical lead times of these plates?

Usually ships within 24-48 hours and customers should receive their orders 2-7 days upon product availability.

How Long Does Body Armor Last?

Prime Armor level III plates a 10-year minimum warranty for the ballistic components. Which is double of the industry standard. With a proper storage/usage our body armor can be used even longer than 10-years.

WARNING: Long-term storage at the temperature over 175ºF will result in a shorter life span of the product.

Reviews

There are no reviews yet.